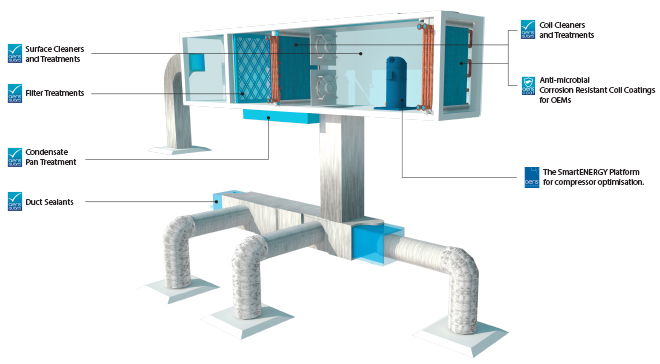

Aeris SmartENERGY uses a whole of system approach to HVAC&R optimisation:

1. Compressor Optimisation

The SmartENERGY technology platform improves energy efficiency by optimising the compressor operation. This is achieved by better matching the heat load using real-time dynamic demand management.

2. Heat Exchanger Optimisation

AerisGuard™ cleans and removes contaminants from coils as well as protecting it from recontamination. This delivers better heat transfer and improved energy efficiency.

3. Air Flow Optimisation

Aeris Duct Sealant minimises efficiency losses by eliminating leaks in ductwork. AerisGuard™ Filter Treatments improve air flow by preventing contaminant build-up.

4. Indoor Air Quality Optimisation

AerisGuard™ patented anti-microbial technology cleans and removes contaminants from coils, filters, water sources and surfaces as well as protecting it from recontamination.

SmartENERGY Technology Platform - Compressor Optimisation

The SmartENERGY technology platform improves energy efficiency by optimising the compressor operation. This is achieved by better matching the heat load using real-time dynamic demand management.

The Aeris SmartENERGY technology platform provides:

Retrofit solution for both new and existing equipment

Improved efficiency and energy savings

Compatibility with most HVAC&R control systems

Complements most BMS functions with comprehensive energy and performance reporting

Prolonged equipment life cycle

Sustained maximised efficiency of systems

Reduced life cycle cost of equipment (cost of ownership)

How does the SmartENERGY Technology Platform work?

Self Learn

The proprietary AERIS SmartENERGY platform measures and records the historical operating patterns of the system.

The self-learn mode applies the best fit control algorithm to determine the most effective operating conditions to achieve the desired temperature.

Adaptive Control

SmartENERGY uses real time dynamic demand and energy management control.

As the room temperature approaches set point, it intuitively turns the compressor off or unloads stages (for fixed speed compressors) or reduces the capacity load (for digital scroll compressors).

As the temperature moves away from set point, it re-engages compressor operation to minimise temperature fluctuations, whilst maximising the compressor efficiency.

Optimises

The real time dynamic demand management cycle is repeated up to 4 times per hour.

This minimises energy consumption and reduces running costs.

Key Features and Benefits

Retrofits to both new and existing HVAC&R equipment.

Real time dynamic demand and energy management platform.

Compressor operation is optimised using proprietary logic.

Reduces energy usage and running costs.

Complements most HVAC&R controls and Building Management Systems.

Applications

Suitable for most air conditioning and refrigeration equipment:

Air cooled/ water cooled HVAC systems.

All fixed speed compressors

Most Variable speed system (Inverter, VAV)

Cool rooms and freezer rooms with single & dual compressor systems.

Multiple compressor rack systems (common in refrigeration)

All fixed speed reciprocating compressors.

Variable speed drive reciprocating compressor (typically the lead compressor) and the remainder fixed speed

Fixed speed screw compressors

Screw compressors with variable speed drive(s)

Turbocore compressors

Refrigerated containers fixed and mobile transport

All Chilled water plant (central plant) including Ammonia systems

Self Learn

Self Learn Adaptive Control

Adaptive Control